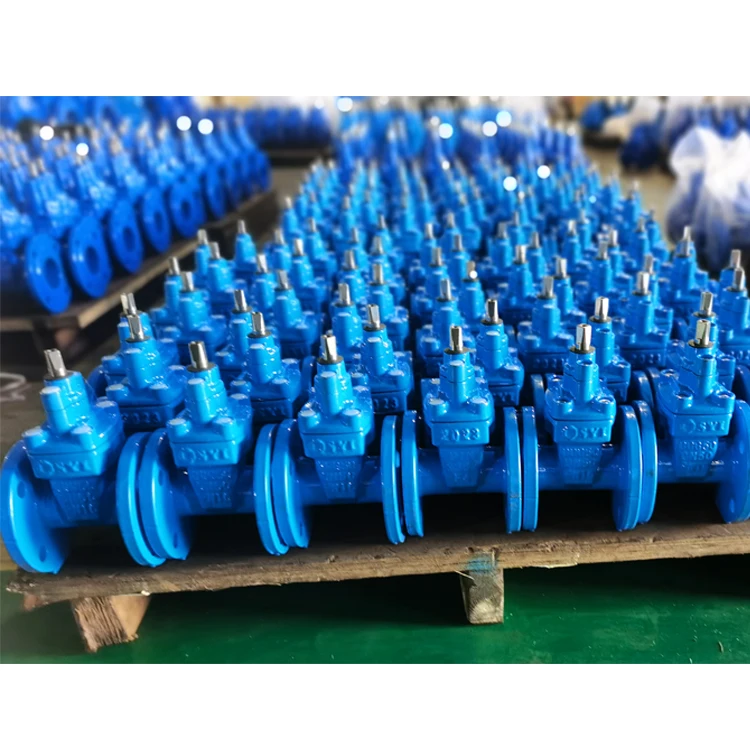

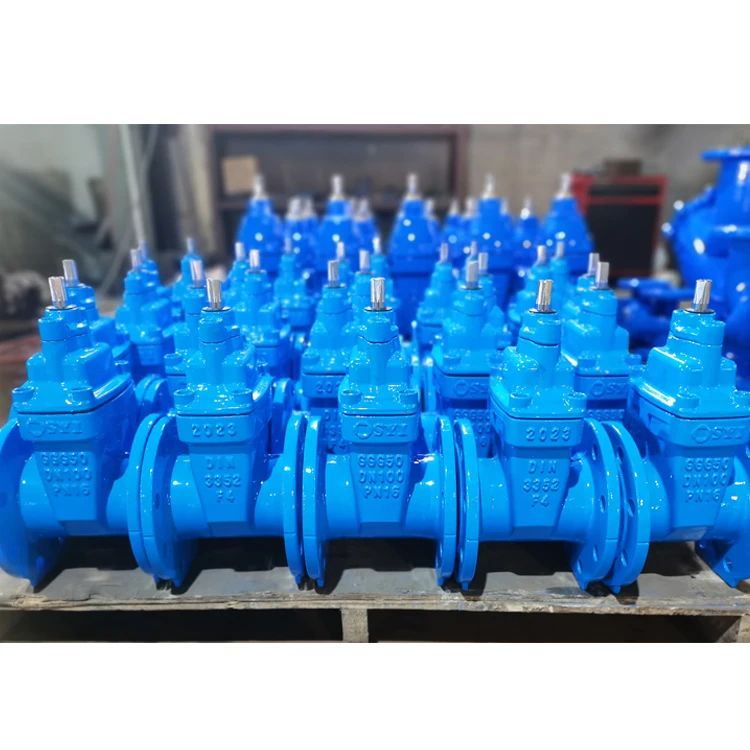

SYI can supply both standard type and COMPACT type DIN 3352 F4 Non-Rising Stem Resilient Seated Gate Valve. SYI COMPACT DIN 3352 F4 Non-Rising Stem Resilient Seated Gate Valve is the light type gate valve, with the newest compact design in the market, more lighter, more easier, and more lower cost, but with the same good quality and better for use.

|

Name

|

DIN 3352 F4 Non-Rising Stem Resilient Seated Gate Valve

|

|

Design

|

DIN3352

|

|

Face to face

|

DIN3202-F4

|

|

Flange drilling

|

DIN2531 / DIN2532 / DIN2533 / EN1092

|

|

Working temperature

|

0-100º C

|

|

Working pressure

|

PN10 / PN16

|

|

|

|

Main Parts and Material:

|

Item

|

Part Name

|

Material

|

Item

|

Part Name

|

Material

|

|

1

|

Body

|

GGG50

|

5

|

Bonnet

|

GGG50

|

|

2

|

Disc

|

GGG50 with NBR/SBR

|

6

|

Handwheel

|

GGG50

|

|

3

|

Stem Nut

|

Brass with GGG50

|

7

|

Brass Nut

|

Brass

|

|

4

|

Stem

|

Stainless Steel/2Cr13

|

Main Dimensions: Unit: mm

|

DN

|

L

|

D

|

|

|

PN10

|

PN16

|

||

|

40

|

140

|

150

|

150

|

|

50

|

150

|

165

|

165

|

|

65

|

170

|

185

|

185

|

|

80

|

180

|

200

|

200

|

|

100

|

190

|

220

|

220

|

|

125

|

200

|

250

|

250

|

|

150

|

210

|

285

|

285

|

|

200

|

230

|

340

|

340

|

|

250

|

250

|

400

|

400

|

|

300

|

270

|

455

|

455

|

|

350

|

290

|

505

|

520

|

|

400

|

310

|

565

|

580

|

|

450

|

330

|

615

|

640

|

|

500

|

350

|

670

|

715

|

|

600

|

390

|

780

|

840

|

|

700

|

430

|

895

|

910

|

|

800

|

470

|

1015

|

1025

|

|

900

|

510

|

1115

|

1125

|

|

1000

|

550

|

1230

|

1255

|

|

1200

|

630

|

1455

|

1485

|

|

1400

|

710

|

1675

|

1685

|

|

1600

|

790

|

1915

|

1930

|

|

1800

|

870

|

2115

|

2130

|

|

2000

|

950

|

2325

|

2345

|

|

For other sizes not mentioned above, please contact us.

We have right to change the data without further notice.

|

|||

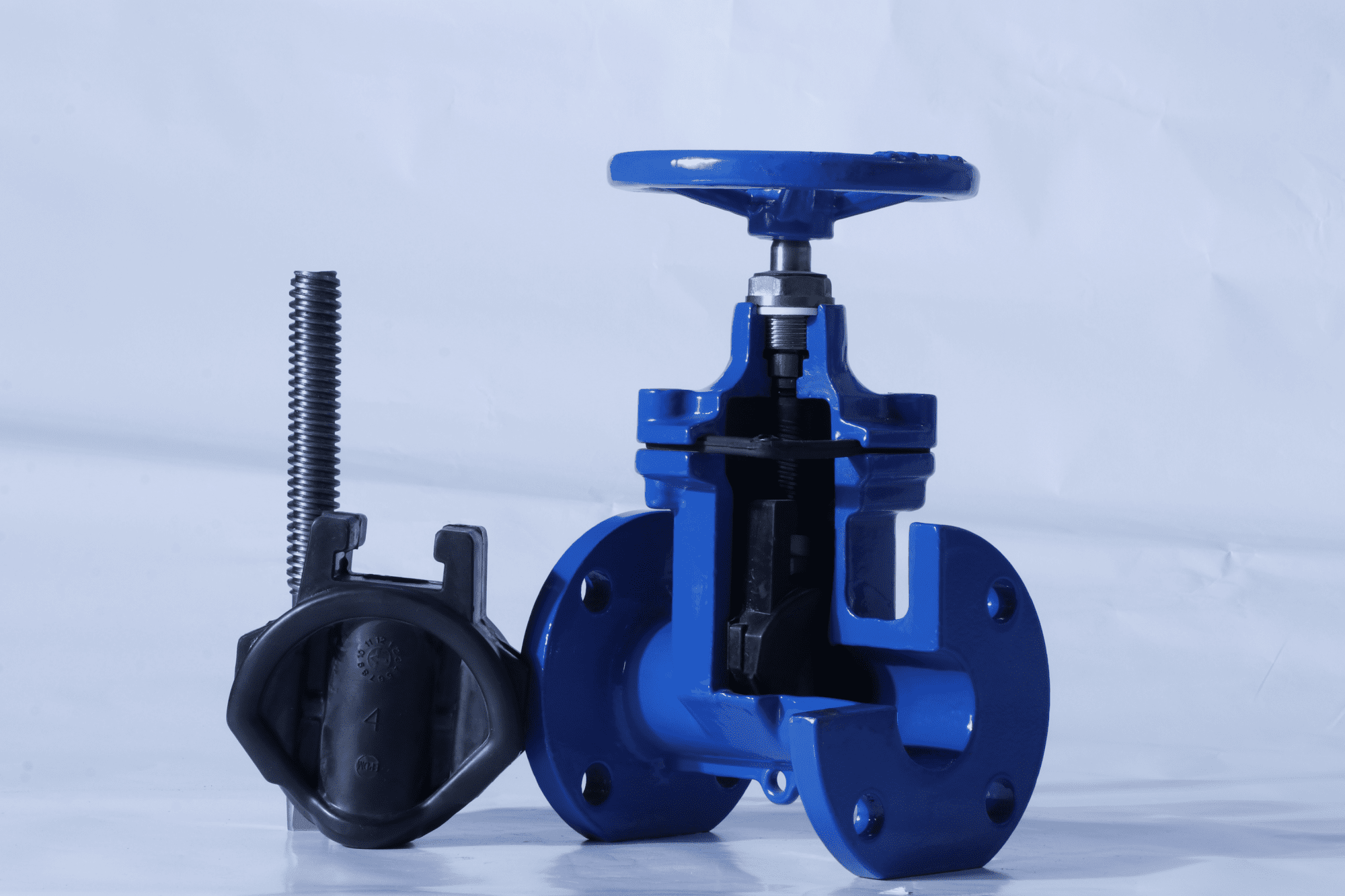

Flat bottom seat ring Integral with the body, inside and outside epoxy resin coating, wedge wholly bonded with rubber. Three “O” ring sealing. These all insure excellent corrosion protection and reliable sealing capability. As per request, SYI COMPACT DIN 3352 F4 Non-Rising Stem Resilient Seated Gate Valve can be actuated by operating lever, hand wheel electrical actuator and so on.

Unique design:

Both Standard type and Compact design

One-piece bonnet

non-rising stem

Stemnut is separated from wedge.no seizing-up

Flat bottom seat ring Insures no dead space

“O”ring design for stem back sealing leads to maintenance free

Excellent Corrosion Protection:

Inside epoxy resin coating or vitreous enamel (upon request)

Outside epoxy resin coating

Socket head cap bolts: sealed with glue on the top

Reliable Health Nature:

Epoxy resin coating complies with the WARS certification

Wedge bonded with rubber for the health inspection

Trims are made of stainless steel or bronze

Scope of Application:

Potable water supply

Industrial fields