SYI manufactures Class 125 Ductile Iron Flanged Fittings for Waterworks, Industrial and fire fighting application. All of our

fittings are manufactured in accordance with ANSI Specification B16.1 and AWWA C110.

fittings are manufactured in accordance with ANSI Specification B16.1 and AWWA C110.

Standard

Material Characteristics:

|

Tensile strength(Mpa)

|

Elongation(%)

|

Brinell hardness(HB)

|

|

≥420

|

≥5

|

≦250

|

100% hydraulitic pressure test for each piece of SYI pipeline products!

|

Material

|

Ductile iron ASTM A536.

|

|

Working Pressure

|

250 PSI

|

|

Coating

|

|

|

Externall coatings:

bitumen painting;zinc +bitumen painting;liquid epoxy painting;epoxy applied by FBE;according to customers’ requirements.

|

Internall coatings:

bitumen painting;cement mortar lining;;liquid epoxy painting;epoxy applied by FBE;according to customers’ requirements.

|

|

Reference Rules

|

Dimensions and testing in accordance with ANSI/AWWA C110/A21.10.

|

Accessiories: Gaskets, bolts & nuts can be suppllied according to customer’s requirements.

Special fittings are available.

Special fittings are available.

SYI’s quality control department maintains strict control over all manufacturing standards. Our fittings are produced to the

following tolerances:

following tolerances:

Mechanical Properties:

Ductile Iron to ASTM A 536 – Minimum Tensile Strength 70,000 psi

Yield Strength 50,000 psi

Elongation 5%

Ductile Iron to ASTM A 536 – Minimum Tensile Strength 70,000 psi

Yield Strength 50,000 psi

Elongation 5%

Chemical Properties:

Phosphorous, Maximum 0.75%

Sulfur, Maximum 0.15%

Phosphorous, Maximum 0.75%

Sulfur, Maximum 0.15%

Dimensional Tolerances:

Center to face distance + or – .03 in.

Wall thickness -0.10 in.

Angle of bends + or – 1/2 degree

Flange thickness +.12 in. – 0 in.

Center to face distance + or – .03 in.

Wall thickness -0.10 in.

Angle of bends + or – 1/2 degree

Flange thickness +.12 in. – 0 in.

As standard procedure SYI hydrostatically tests every fitting to insure quality casting integrity. These tests are performed at 1.5 times the rated working pressure.

At the buyers request SYI will also provide fittings cement-lined and tar-coated in accordance with ANSI A 21.4 and AWWA C104. SYI fittings are provided with either a tar coated or epoxy primed exterior surface at the customers discretion.

Ductile iron pipe fitting is a kind of fitting casted from spherical graphite cast iron. The greater

performance of ductile iron makes it possible to improve the design of fittings and to reduce their dimensions. This makes it easier to lay mains in congested urban areas of large towns, and results in a reduction in the size of valve chambers, the

dimensions of which depend mainly on the space occupied by the fittings. It usually is used for jointing the pipelines for water,other liquids, or gas, with or without pressure, installed below or above ground, it allows pipeline deviation, change of

direction or bore.

performance of ductile iron makes it possible to improve the design of fittings and to reduce their dimensions. This makes it easier to lay mains in congested urban areas of large towns, and results in a reduction in the size of valve chambers, the

dimensions of which depend mainly on the space occupied by the fittings. It usually is used for jointing the pipelines for water,other liquids, or gas, with or without pressure, installed below or above ground, it allows pipeline deviation, change of

direction or bore.

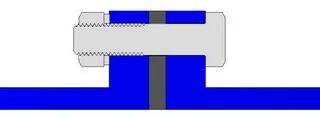

Note:The gaskets, bolts & nuts are supplied separately with the fittings usually.

SYI manufactures a full range of Ductile Iron Pipe Fittings according to ISO 2531, EN545, EN598, ANSI/AWWA C110, C153 and other major standards.

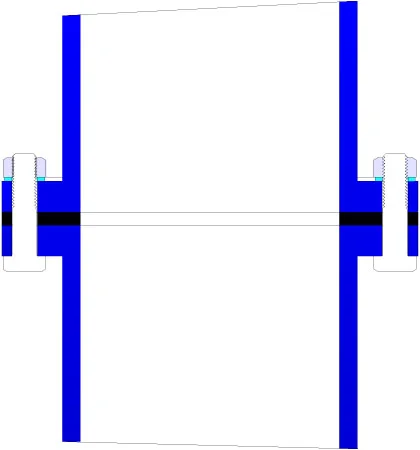

-Flanged pipe fittings,

-Loosing flanged pipe fittings,

-Push-in socket pipe fittings (Tyton),

-Mechanical Joint socket pipe fittings (MJ),

-Express socket pipe fittings (EX),

-Fittings for uPVC pipes,

-Fittings for PE pipes,

-Other Pipeline Accessories.