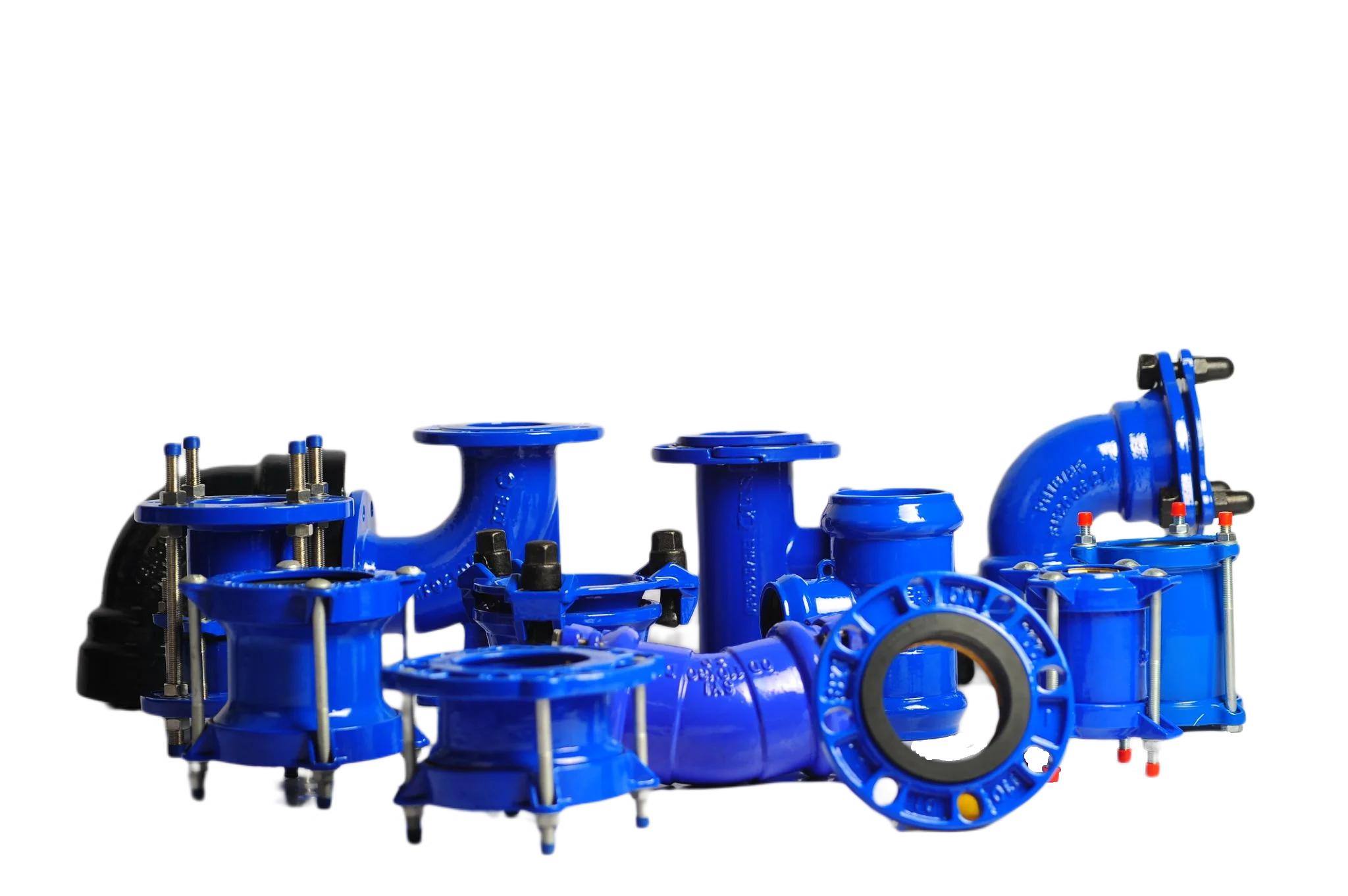

Ductile Iron Compact Fittings For Pe Pipes En 12842 Iso 2531 En 545 En598 For Water Or Sewerage Pipeline Projects

SYI COMPACT Fittings For PE Pipes Is The Newest Design In The Market, Syi Can Supply The Ductile Iron Pipe Fittings Both For Pe And Pvc Pipes, Indlucing Tee, Bend, Taper, Cap, Duckfoot Bend And So On, From Dn80 To Dn300, With The Coating Of Zinc And Black Bitumen Coating, Red/Blue Epoxy Coating, Or Pu (Polyurethane) Coating.

SYI COMPACT Fittings For PE Pipes Feature

Used For Jointing Both Pvc And Pe Pipes, Sealing Is Obtained By Applying Pressure To The Gasket By Gland. Pe Pipe Fittings Permit Significant Angular Deflextion Both During And After Installation And Can Accept a Light Offset Of The Centreline. Note:The Gaskets, Bolts & Nuts Are Supplied With The Fittings Usually.

1. The structural design was completed in 2014, now they are very mature. 2. Technology upgrades make them with similar advantages of PVC pipe fittings (High quality casting surface; Perfect sealing performance; Reasonable structure). 3. Owing to the copper ring structure, SYI COMPACT PE/PVC Pipe Fittings have the anti sliping function under pressure. As they have tee, bend, flange socket and so on, they are more flexible and convenient during the connection.

|

Material

|

||||

|

Fittings and Gland

|

Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083.

|

|||

|

Gasket

|

Rubber E.P.D.M./NBR/SBR in accordance with EN 681.1

|

|||

|

Working Pressure

|

16 Bar or 250 PSI

|

|||

|

Fluid Temperature

|

0°C-50°C, excluding frost.

|

|||

|

Coating

|

Externall coatings

|

Zinc coating +bitumen painting

|

According to customers’ requirements |

|

|

Liquid epoxy painting

|

||||

|

Epoxy applied by FBE

|

||||

|

Internall coatings

|

Cement mortar lining

|

According to customers’ requirements |

||

|

Liquid epoxy painting

|

||||

|

Epoxy applied by FBE

|

||||

|

Reference Rules

|

Dimensions and testing in accordance with ISO 2531/EN 545 and EN 12842.

|

|||

|

Accessiories

|

Gaskets, bolts & nuts can be suppllied according to customer’s requirements.

|

Special fittings are available.

|

||

Product description • The pipe restraining system is seperate from the sealing system. • By tightening the screws the lock ring presses the grip ring against the pipe and a restraint connection is produced. • Inserting the pipe end in the sealing chamber is possible without a lot of effort. • For PE and PVC pipes (DIN 8074, EN 1452-2).

Technical features • Body: GJS-400, epoxy powder-coated • For thin-walled PE pipes up to a wall thickness of 3 mm a support liner must be used • Max. operating pressure: 16 bar • Flange measured and drilled in accordance with EN 1092-2-PN 10 (Standard); EN 1092-2-PN 16 for DN 200 mm please specify when ordering – other standards on request!

SYI COMPACT PE/PVC Pipe Fittings—The Newest Design!

√ Most reasonable √ Most light √ Most competitive √ Quality & Efficiency improved

|

Standard

|

|||

|

Material Characteristics

|

Tensile strength/Mpa

|

Elongation/%

|

Brinell hardness/HB

|

|

≥420

|

≥5

|

≦250

|

|

|

100% Hydraulitic pressure test for each piece of SYI pipeline products!

|

|||

|

Production Process

|

||

|

1.Pattern Making

|

More than 4,000 patterns are ready

|

|

|

2.Sand Mixing System

|

Computerized sand mixing system

|

|

|

3. Moulding |

A. Automatic Machine Moulding Line

|

180 times compare with manual moulding

Accurate dimensions Perfect surface Less grinding

100% pressure qualification rate

|

|

B. Manual Moulding

|

Flexible for small quantity demand

|

|

|

C. Lost Foam Moulding

|

Especially for mid and big size fittings and special fittings

|

|

|

4. Pouring

|

By medium frequency furnace

|

|

|

5.Castings Cleaning

|

6. Shot Blasting and Grinding

|

|

|

7.Hydraulic Pressure Testing

|

100% testing

|

|

|

8.Machining

|

Dedicated machining equipments

|

|

|

9.Coating and Lining |

A : Cement Lining

|

|

|

B : Zinc and Bitumen Painting

|

||

|

C : Epoxy Resin Liquid Painting

|

||

|

D : FBE ( Fusion Bonded Epoxy ) Coating Different Powders upon your request FBE

|

||

|

10.Accessories

|

Rubber gaskets, bolts & nuts, copper rings & other accessories are all produced in-house.

|

|