SYI COMPACT MJ Mechanical Joint Socket Pipe Fittings is the newest design, most light, most competitive ductile iron MJ fittings in the market. SYI can supply the MJ fittings from DN80 to DN600, according to ISO 2531, EN 545, and EN598 for water, sewerage, or fire fighting pipeworks with the coating of Zinc and Black Bitumen coating, Red/Blue Epoxy coating, or PU (polyurethane) coating.

|

Name

|

Mechanical Joint Pipe Fittings

|

|

Material

|

Body:Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083.

Gland:Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083. Gasket:Rubber E.P.D.M./NBR/SBR in accordance with EN 681.1 T bolts and nuts:Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083 |

|

Working Pressure

|

40 Bar

|

|

Fluid Temperature

|

0°C-50°C, excluding frost.

|

|

Coating

|

External Coatings:

zinc coating +bitumen painting;liquid epoxy resin painting;epoxy applied by FBE;according to customers’ requirements. Internal Coating: cement mortar lining;liquid epoxy resin painting;epoxy applied by FBE;according to customers’ requirements. |

|

Reference Rules

|

Dimensions and testing in accordance with ISO 2531/EN 545

|

|

Use

|

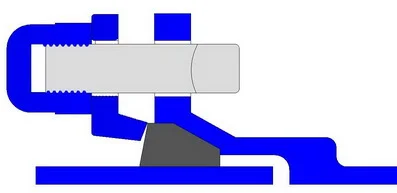

For mechanical joint fittings,sealing is obtained by applying pressure to the gasket by gland.MJ fittings permits significant

angular deflextion both during and after installation and can accept a light offset of the centreline. |

|

|

|

For Mechanical joint, sealing is obtained by applying pressure to the gasket by gland. MJ fittings permits significant angular deflextion both during and after installation and can accept a light offset of the centreline.

Note:The gaskets, bolts & nuts are supplied with the fittings usually.

SYI COMPACT EX Express Joint Socket Pipe Fittings—The Newest Design!

* Most reasonable

* Most light

* Most competitive

* Quality & Efficiency improved

* Most light

* Most competitive

* Quality & Efficiency improved

* Stock available

Updated gland of EX Express Joint Socket Pipe Fittings, which can connect with the restrained system freely.

Compact MJ Mechanical Joint Socket Pipe Fittings Pattern List

|

SYI Series No.

|

DN

|

|

mm

|

|

|

Loosing Flanged Socket

|

|

|

EMJLS80

|

80

|

|

EMJLS100

|

100

|

|

EMJLS150

|

150

|

|

EMJLS200

|

200

|

|

EMJLS250

|

250

|

|

EMJLS300

|

300

|

|

Double Socket Collar

|

|

|

UMJ80

|

80

|

|

UMJ100

|

100

|

|

UMJ125

|

125

|

|

UMJ150

|

150

|

|

UMJ200

|

200

|

|

UMJ250

|

250

|

|

UMJ300

|

300

|

|

Loosing Flanged Socket Sleeve

|

|

|

EUMJLS80

|

80

|

|

EUMJLS100

|

100

|

|

EUMJLS150

|

150

|

|

EUMJLS200

|

200

|

|

EUMJLS250

|

250

|

|

EUMJLS300

|

300

|

|

EX Double Socket 45 Deg Bend

|

|

|

MMK45EX80

|

80

|

|

MMK45EX100

|

100

|

|

MMK45EX125

|

125

|

|

MMK45EX150

|

150

|

|

MMK45EX200

|

200

|

|

MMK45EX250

|

250

|

|

MMK45EX300

|

300

|

|

Double Socket Tee with Loosing Flange Branch

|

|

|

MMAMJLS8080

|

80*80

|

|

MMAMJLS10080

|

100*80

|

|

MMAMJLS100100

|

100*100

|

|

MMAMJLS15080

|

150*80

|

|

MMAMJLS150100

|

150*100

|

|

MMAMJLS150150

|

150*150

|

|

MMAMJLS20080

|

200*80

|

|

MMAMJLS200100

|

200*100

|

|

MMAMJLS200150

|

200*150

|

|

MMAMJLS200200

|

200*200

|

|

MMAMJLS25080

|

250*80

|

|

MMAMJLS250100

|

250*100

|

|

MMAMJLS250150

|

250*150

|

|

MMAMJLS250200

|

250*200

|

|

MMAMJLS250250

|

250*250

|

|

MMAMJLS30080

|

300*80

|

|

MMAMJLS300100

|

300*100

|

|

MMAMJLS300150

|

300*150

|

|

MMAMJLS300200

|

300*200

|

|

MMAMJLS300250

|

300*250

|

|

300*300

|

|

|

Double Socket Bend

|

|

|

MMK11MJ80

|

80*11.25°

|

|

MMK22MJ80

|

80*22.5°

|

|

MMK45MJ80

|

80*45°

|

|

MMQMJ80

|

80*90°

|

|

MMK11MJ100

|

100*11.25°

|

|

MMK22MJ100

|

100*22.5°

|

|

MMK45MJ100

|

100*45°

|

|

MMQMJ100

|

100*90°

|

|

MMK11MJ150

|

150*11.25

|

|

MMK22MJ150

|

150*22.5°

|

|

MMK45MJ150

|

150*45°

|

|

MMQMJ150

|

150*90°

|

|

MMK11MJ200

|

200*11.25°

|

|

MMK22MJ200

|

200*22.5°

|

|

MMK45MJ200

|

200*45°

|

|

MMQMJ200

|

200*90°

|

|

MMK11MJ250

|

250*11.25°

|

|

MMK22MJ250

|

250*22.5°

|

|

MMK45MJ250

|

250*45°

|

|

MMQMJ250

|

250*90°

|

|

MMK11MJ300

|

300*11.25°

|

|

MMK22MJ300

|

300*22.5°

|

|

MMK45MJ300

|

300*45°

|

|

MMQMJ300

|

300*90°

|