SYI can supply Ductile Iron Tyton Push-in Joint Socket Pipe Fittings from DN80 to DN2000, with the coating of Zinc and Black Bitumen coating, Red/Blue Epoxy coating, or PU (polyurethane) coating.

Standard

Material Characteristics:

|

Tensile strength

Mpa |

Elongation

% |

Brinell hardness

HB |

|

≥420

|

≥5

|

≦250

|

100% hydraulitic pressure test for each piece of SYI pipeline products!

|

Material

|

Fitting:Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083.

|

|

|

Gasket:Rubber E.P.D.M./NBR/SBR in accordance with EN 681.1

|

||

|

Working Pressure

|

40 Bar.

|

|

|

Fluid Temperature

|

0°C-50°C, excluding frost.

|

|

|

Coating

|

Externall coatings:

zinc +bitumen painting;

liquid epoxy resin painting;

epoxy applied by FBE;

according to customers’ requirements.

|

Internall coatings:

cement mortar lining;

liquid epoxy resin painting;

epoxy applied by FBE;

according to customers’ requirements.

|

|

Reference Rules

|

Dimensions and testing in accordance with ISO 2531/EN 545.

|

|

|

Accessiories

|

Gaskets, bolts & nuts can be suppllied according to customer’s requirements.

|

|

Ductile iron pipe fitting is a kind of fitting casted from spherical graphite cast iron. The greater

performance of ductile iron makes it possible to improve the design of fittings and to reduce their dimensions. This makes it easier to lay mains in congested urban areas of large towns, and results in a reduction in the size of valve chambers, the

dimensions of which depend mainly on the space occupied by the fittings. It usually is used for jointing the pipelines for water, other liquids, or gas, with or without pressure, installed below or above ground, it allows pipeline deviation, change of direction or bore.

performance of ductile iron makes it possible to improve the design of fittings and to reduce their dimensions. This makes it easier to lay mains in congested urban areas of large towns, and results in a reduction in the size of valve chambers, the

dimensions of which depend mainly on the space occupied by the fittings. It usually is used for jointing the pipelines for water, other liquids, or gas, with or without pressure, installed below or above ground, it allows pipeline deviation, change of direction or bore.

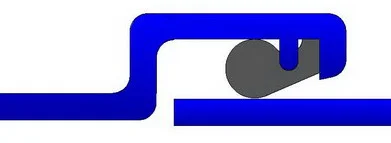

Push-in Flexible Joint (Tyton) can be assembled by pushing the spigot through the gasket in the socket of the mating component, and permits significant angular deflextion both during and after installation and which can accept a light offset of the centreline.

Note:The gaskets are supplied with the fittings usually.

Packing & Delivery

Different package upon your request,like wood cases & pallets,ply-wood crates & pallets,steel crates & pallets and etc.